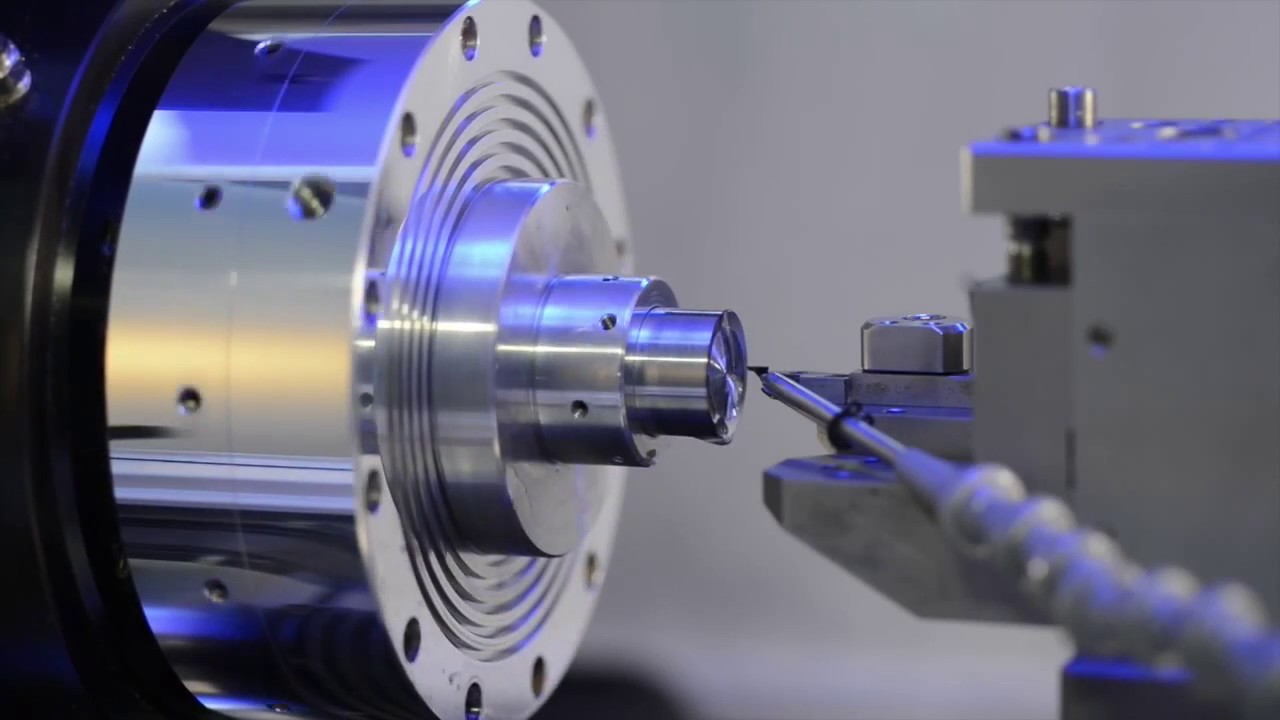

In aerospace, precision isn’t optional—it’s a life-saving necessity. From jet engines to satellite optics, tiny imperfections can cause major failures. With ultra‑precision machining, manufacturers achieve sub-micron accuracy and flawless finishes essential for reliability, safety, and performance.

1. Why Tighter Tolerances Mean Safer Flights

Aerospace components must meet exact dimensional tolerances—often within a few micrometers. This precision ensures seamless assembly and optimal performance, preventing parts from failing under extreme load or high-altitude conditions. Using diamond-based tools enables manufacturers to consistently hit these tolerances, enhancing overall system integrity.

2. Surface Finish: Beyond Shine, It’s Performance

A smooth surface finish reduces aerodynamic drag and improves fatigue resistance. Research shows ultra‑precision machining delivers nanometer-level finish quality—vital for turbine blades, optical sensors, and fuselage components. Diamond tools, with their unmatched hardness, maintain sharp edges longer, ensuring consistent results and lower risk of surface micro-cracking.

3. Durability Meets Material Compatibility

Aerospace materials like titanium alloys, CFRPs, and nickel superalloys challenge conventional tooling. Ultra‑precision machining using PCD (polycrystalline diamond) and CBN excels at machining these materials without tool degradation or heat-induced distortion. This not only improves accuracy but also extends tool life and production uptime.

4. Consistency Yields Manufacturable Quality

Every aircraft part must be identical, batch after batch. Ultra‑precision machining ensures tight tolerances and surface quality are maintained consistently, reducing defect rates and costly rework. High repeatability safeguards compliance with strict aerospace standards.

5. Driving Innovation: What Today’s Aerospace Components Require

Emerging tech—like UAVs, hypersonic vehicles, and optical navigation systems—demands complex geometries and flawless finishes. Ultra‑precision machining enables these innovations, letting engineers craft lightweight mirrors and conformal surfaces that fit exacting specs without further polishing

Ultra‑precision machining isn’t just a step in aerospace manufacturing—it’s the foundation of safety, performance, and innovation. By embracing diamond-based tooling and cutting-edge machining processes, aerospace manufacturers can build lighter, faster, and more reliable aircraft.

Ready to elevate your aerospace components?

At Hardten Precision Technologies, we deliver ultra‑precision diamond tooling tailored for aerospace needs. For a consultation or tool recommendation.