The manufacturing industry has seen remarkable advancement with ultra-precision diamond tools.

These tools have revolutionized how manufacturers approach machining, enabling them to achieve

higher accuracy levels and surface finishes. These tools are essential in producing components with

intricate geometry and exceptional details, a necessity in sectors like aerospace, automotive and

medical devices. Their profound impact reduces the need for secondary finishing processes and

ensures a higher-quality end product right from the machining stage

Current Innovations in Ultra-Precision Diamond Tools

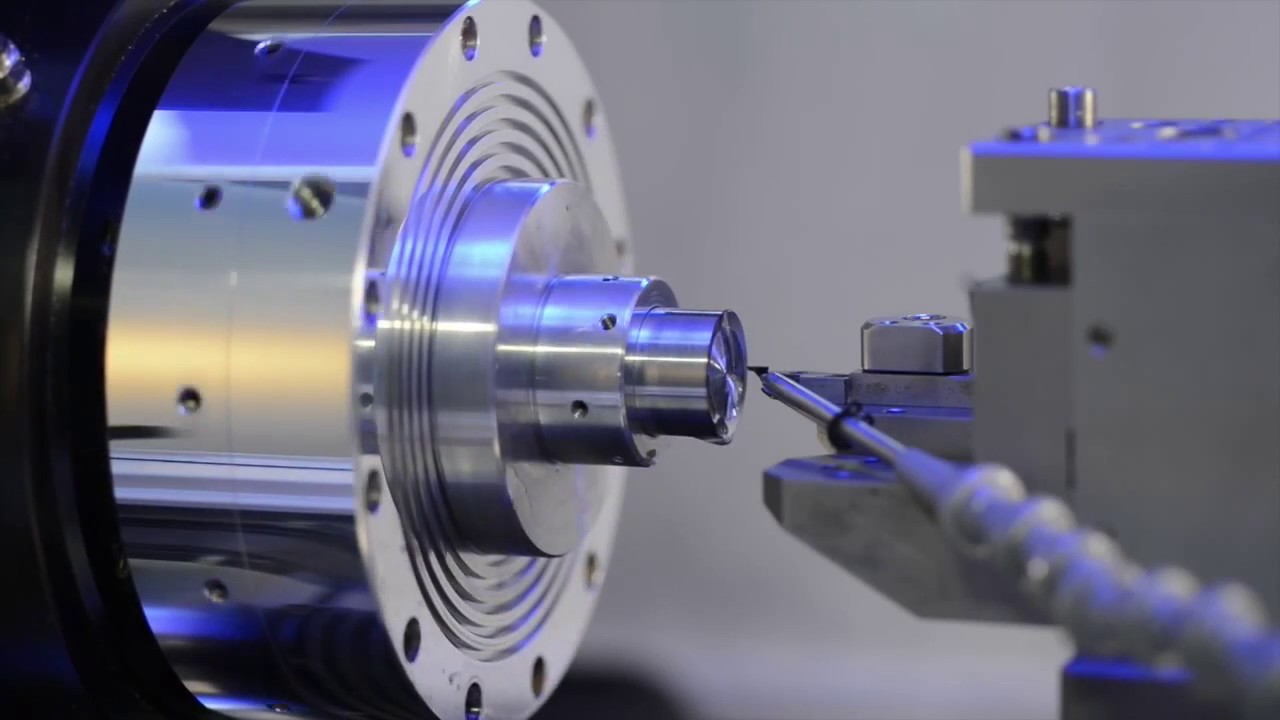

Techniques in ultra-precision diamond turning have made remarkable progress, and ultra-precision

diamond tools are integral to it. These tools, known for their exceptional hardness and sharpness,

enable sub-nanometer accuracy and Angstrom-level surface finishes in dingle-point diamond turning

(SPDT). Their integration with fast tool servo (FTS) systems and deterministic microgrinding (DMG)

enhances machining versatility and precision. By ensuring consistent quality and efficiency, diamond

tools support the creation of complex geometries and superior surface finishes across various hightech industries, solidifying their role as essential components in modern manufacturing.

In SPDT, diamond tools’ high hardness and sharp edges enable superior surface finishes and

consistent precision. When combined with FTS systems, these tools handle rapid adjustments for

intricate geometries. In DMG, diamond tools ensure precise material removal and fine surface

quality. Their exceptional durability reduces wear, enhancing efficiency and reliability. This versatility

across different machining processes underscores their critical role in achieving high accuracy, fine

finishing, and consistent quality in various industries, from optics to aerospace.

Hardten’s Role in the Industry

At Hardten, we take pride in saying that we’re the pioneers of “make in India” in this sector, with a

significant presence in the Indian manufacturing landscape. Through a combination of advanced

technology and our commitment to excellence, we provide precision tools that meet the most

stringent industry requirements. Our tools are employed in various critical applications, including:

Achieving Form accuracy: Here, achieving form accuracy in diamond tooling is a top priority,

ensuring precise, consistent, and high-performance results that elevate product quality and boost

operational efficiency across industries.

Enhanced Surface Finish: Our tools can deliver a surface finish up to sub-nanometer, which is vital for

high-performance components requiring minimal friction and wear. This precision is vital for

components where surface integrity is paramount, such as in the optics and electronics industries.

Our clients span across multiple industries in India, benefiting from the unparalleled accuracy and

efficiency that our tools provide.

The Future Roadmap

Our vision is to be the most reliable solution provider for diamond tools and technology-driven

industries. We foresee a future where every manufacturing sector relies on precision tools to

minimize production time and maintain consistent quality.

Key aspects of our roadmap include:

Consistent Quality and Performance: Precision tools ensure that every component in a batch meets

the same high standards, enhancing the reliability and performance of the final products.

Economic Viability: Our tools are economically viable, offering long-term cost savings by reducing the

frequency of tool replacements and minimizing material waste.

Tool life: Diamond, the hardest inert material, ensures our tools do not wear out easily, providing

prolonged service life and maintaining performance over time.

Customization: Because no one size fits all, we tailor our diamond tools to meet the unique

specifications of each client, ensuring optimal performance for their specific applications. By

collaborating closely with our clients, we deliver precision tools that align perfectly with their

manufacturing needs and challenges.

Conclusion

Ultra-precision diamond tools are at the forefront of manufacturing innovation and advancing in

accuracy, efficiency, and sustainability. Our commitment to providing top-notch precision tools and

comprehensive support ensures that our clients meet the highest quality standards. Our focus for

the future, remains on pushing the boundaries of what is possible with precision tooling, ensuring

that our clients stay ahead in a competitive market.