Ophthalmic

Clear Vision with Ultra-Precision Crafting Visual Excellence with Ultra-Precision

Our tools play a crucial role in manufacturing intraocular lenses (IOLs) and other optical applications. IOLs are implanted in the eye to treat cataracts and correct vision problems. These precision-crafted tools ensure the utmost accuracy and quality, enabling better vision outcomes for patients. Additionally, we cater to the production of contact lenses, providing the industry with top-notch tools for exceptional comfort and visual aesthetics. From innovative IOLs to advanced contact lenses, our commitment to precision technology is reshaping the eyecare landscape.

Applications

Crafting Excellence

in Industries

For IOL

Whether from direct lathing or moulded pins, machine precision and tool radius tolerance ensure lens quality. Efficient haptic machining reduces per-lens tooling costs.

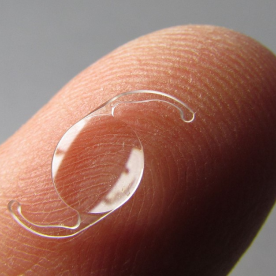

For Contact Lenses

The exacting tolerances of these tools are essential for crafting high-quality contact lenses, ensuring accuracy and quality in both direct lathing and form-pressed methods.

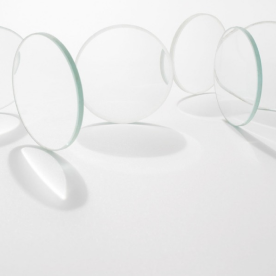

For Spectacle Lenses

Prescription spectacle lenses demand precise diamond tools for shaping and powering, essential for quality and cost-efficiency in various generator machines.