Ultra-Precision Diamond Tools

Hardten Precision Technologies pioneers the art of specialized engineered CVD tooling, delivering performance that powers the world’s most advanced industries — from aerospace and optics to automotive and defense.

0

Years in Diamond Industry

0

Specialized Tool Lines

0

Services We Provide

-- Why Choose Us

Engineered to Exactitude

Hardten Precision Technologies stands for trust, engineering excellence, and customer focus. With our state-of-the-art CVD diamond tooling, precision inspection systems, and proven process consistency, we deliver unmatched surface accuracy and material durability across industries.

Cutting-Edge Accuracy

From Uncontrolled (2000–900nm) to Ultra-Controlled (<50nm) waviness, our advanced CVD and PCD tools guarantee superior surface finishing and reliability for varied industrial needs.

Innovation-Driven R&D

Our dedicated research teams leverage advanced technologies and prototypes to ensure constant improvements in efficiency and precision.

Global Manufacturing Strength

With robust production capabilities, we ensure consistent quality, timely delivery, and efficient solutions tailored to customer demands worldwide.

-- Industries We Serve

CVD Tools That Powers Every Industry

From electro-optics to aerospace, Hardten tools enable industries to achieve flawless machining and superior finish quality.

Ophathalmic

Hardten’s specially engineered CVD diamond tools are designed to meet the unique challenges of the Ophthalmic sector — delivering unmatched accuracy, durability, and sustainability.

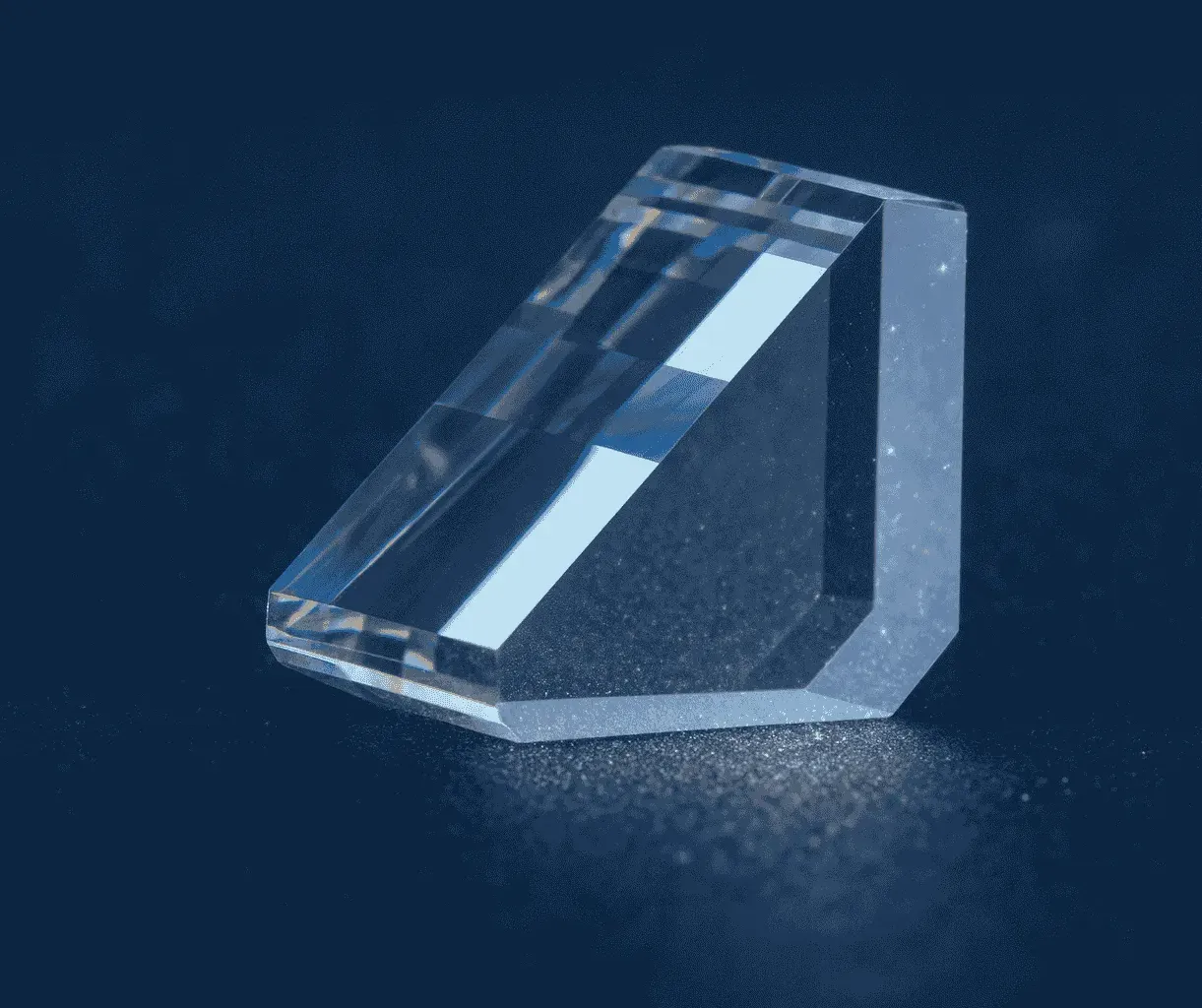

Electro-Optics

Diamond tools engineered to support the growing demands of imaging, sensing, and optical component manufacturing.

Roto-Gravure

Hardten’s highly specialized CVD diamond tools empower gravure printing with sharper engravings, reduced ink waste, and unmatched consistency across large-scale runs

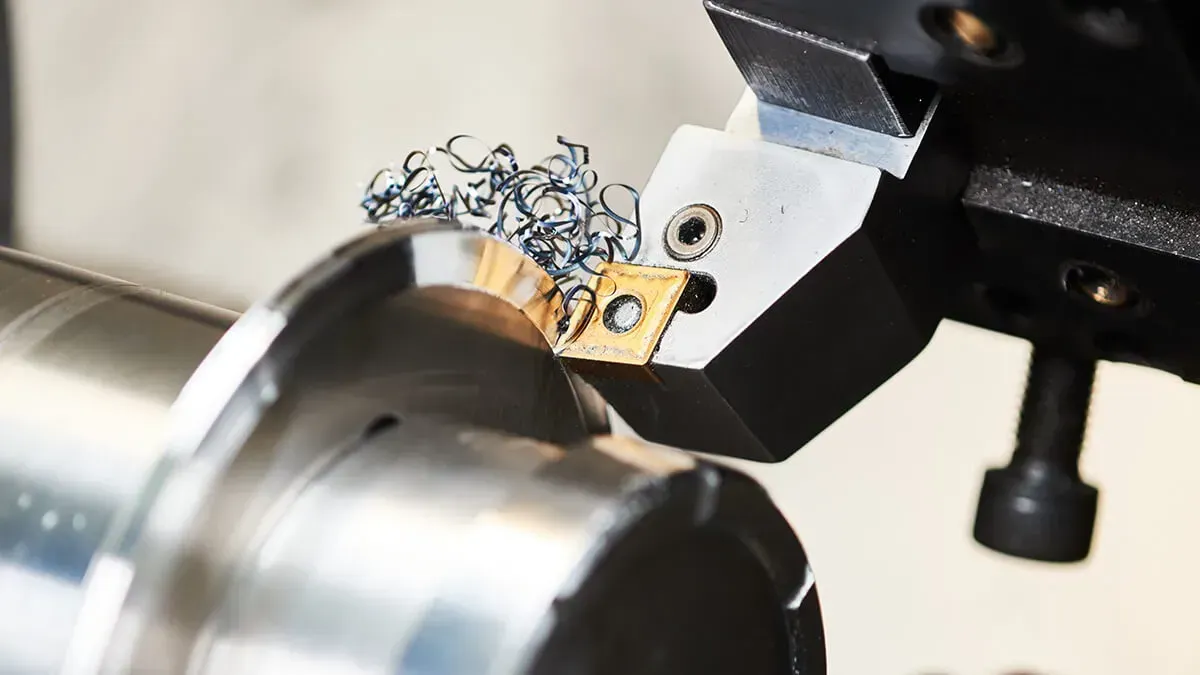

Automotive

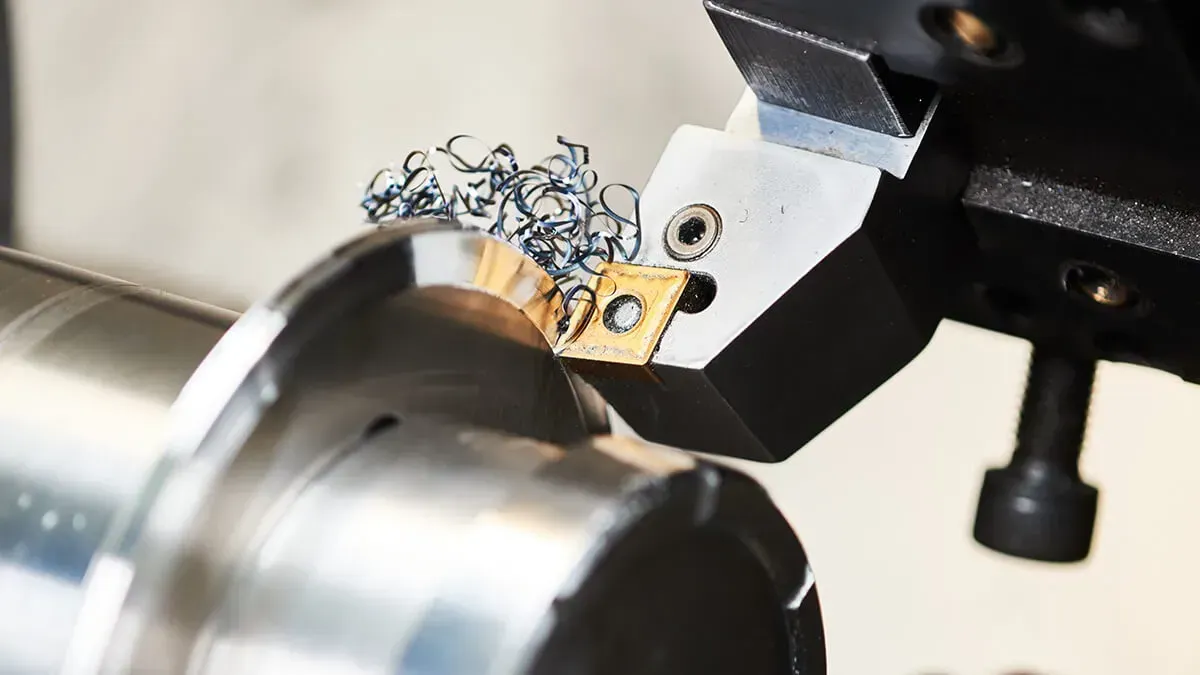

From alloy wheels to engine blocks, Hardten tools deliver the precision and durability needed to power modern automotive innovations.

Aerospace

From jet engines to specialized jigs, Hardten tools deliver unmatched accuracy and consistency to meet the aerospace sector’s toughest standards.

Space & Defense

Hardten’s ultra-precision tools enable the machining of advanced materials for mission-critical space and defence applications.

Watch and Jewelry

Hardten’s ultra-precision tools are trusted in the global watch and jewelry industry to shape, polish, and finish with the highest quality craftsmanship.

Driving Innovation Through Research & Development

At Hardten, R&D is not a department — it’s the core of everything we do. From material science to nano-controlled processes, our research fuels precision, sustainability, and global competitiveness.

-- Our Tools Categories

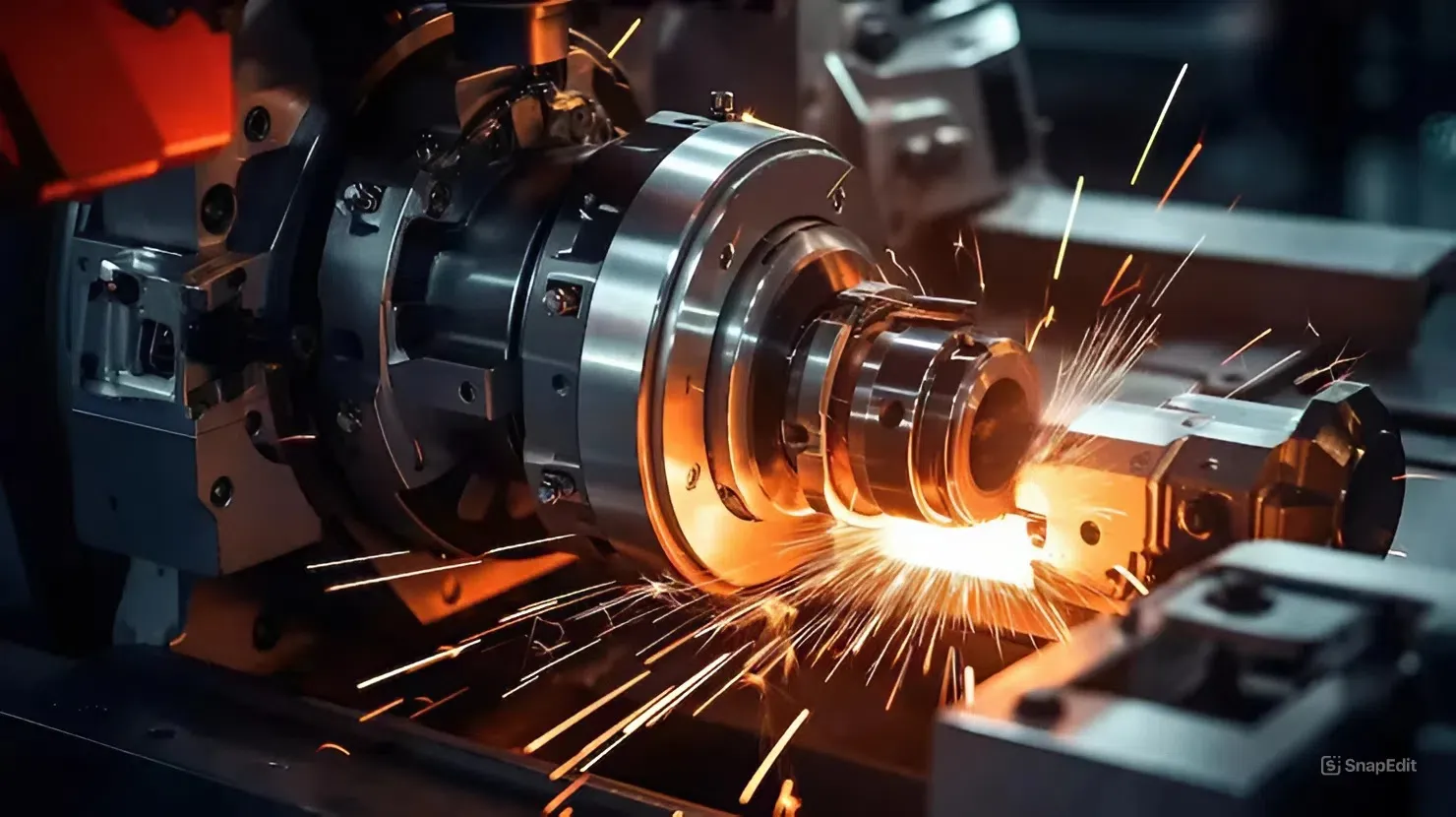

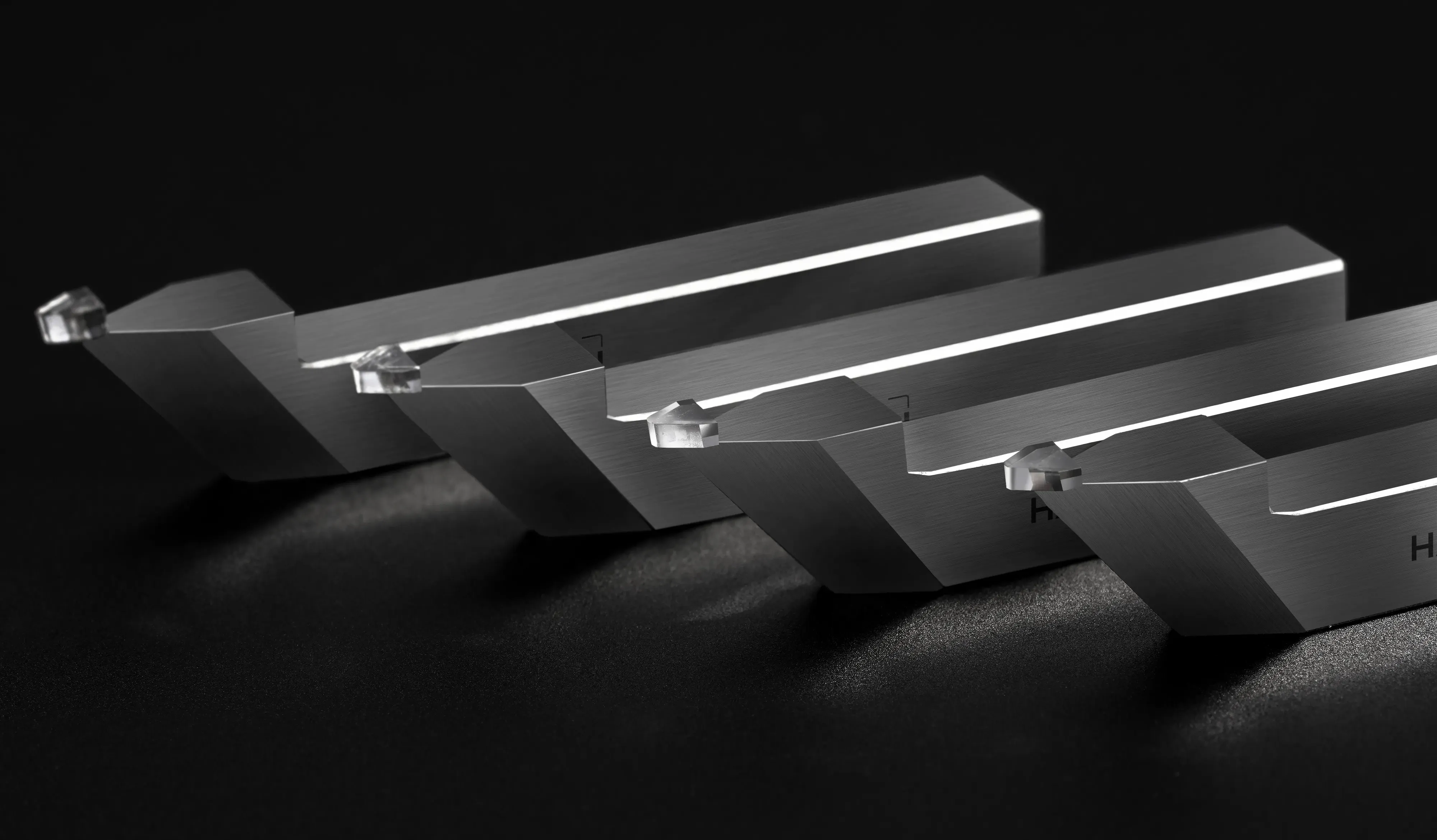

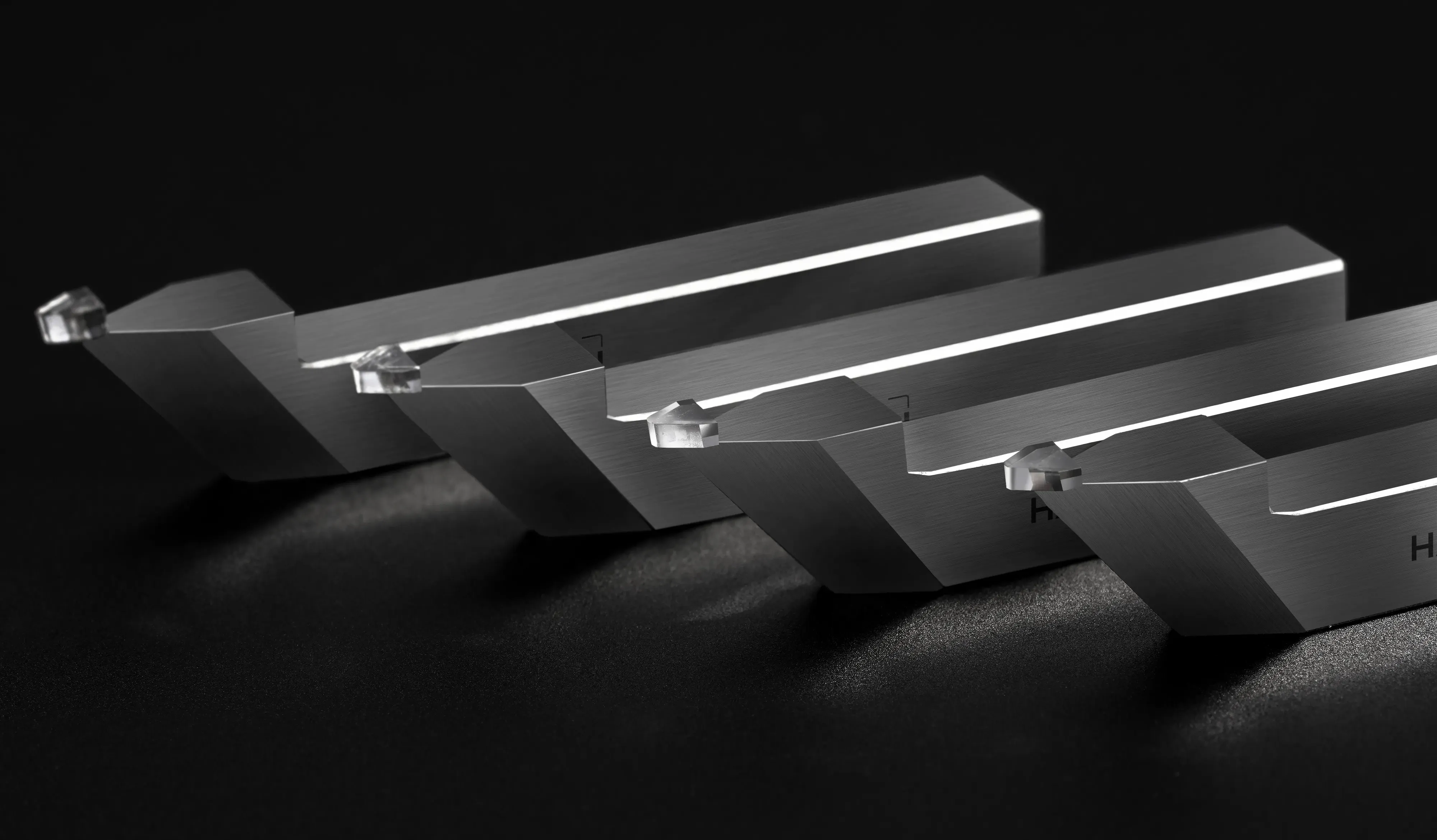

Tools That Shape the Future of Manufacturing

Every Hardten tool is the result of rigorous testing and years of material science expertise.

-- Our SERVICES

Services That Refine Every Edge

Beyond manufacturing, we provide expert services designed to enhance tool longevity and consistency.

01

Tool Relaping

Restoring cutting geometry to as-new performance.

LEARN MORE

Tool Relaping

Restoring cutting geometry to as-new performance.

02

Technical Reports

Detailed tool performance analytics and diamond profiling.

LEARN MORE

Technical Reports

Detailed tool performance analytics and diamond profiling.

03

Diamond Tool Consultancy

Personalized selection and optimization guidance for critical production lines

LEARN MORE

Diamond Tool Consultancy

Personalized selection and optimization guidance for critical production lines

04

Ultra-Controlled <50 nm

With Global Standard Machinery We Are Able To Ensure <50 nm Waviness Tool For Special Applications.

LEARN MORE

Ultra-Controlled <50 nm

With Global Standard Machinery We Are Able To Ensure <50 nm Waviness Tool For Special Applications.

-- Innovation with Responsibility

Sustainability Through Smart Engineering

At Hardten Precision Technologies, we believe true precision means caring for the world around us. Sustainability is integral to how we operate — from our shop floor to our supply chain. Our production runs on 100% committed in reducing carbon emissions

Solar panels are already powering part of our facilities, and wind energy integration is underway to further reduce our carbon footprint. We’ve also invested in proper industrial waste processing and management to handle materials responsibly and minimize environmental impact.

100%

Electric power — no diesel, no fuel burning

50%+

Facilities already powered by renewable energy

0%

Industrial waste mismanagement — proper processing systems in place

1 Tree

Planted by every employee, restoring green spaces

-- Trusted Worldwide

World-Class

Certifications

Every certification reflects our promise of reliability, sustainability, and customer-first excellence.

Get the Right Tool for Your Business Needs

Whether you need turning, milling, grinding, or polishing solutions — our experts are here to match you with the tool that fits your industry and application.